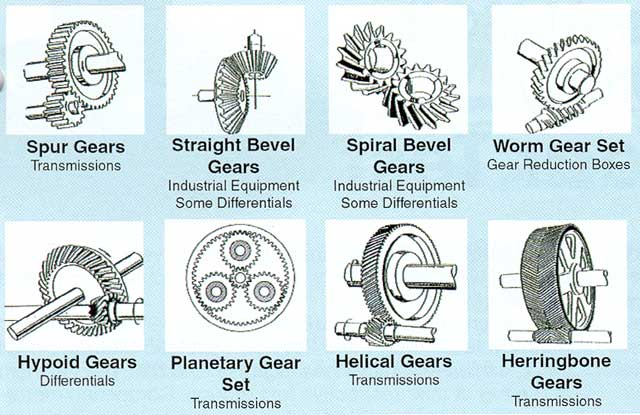

Gear Types

|

|

External vs. internal gears

An

external gear is one with the teeth formed on the outer surface of a

cylinder or cone. Conversely, an internal gear is one with the teeth

formed on the inner surface of a cylinder or cone. For bevel gears, an internal

gear is one with the pitch angle exceeding 90 degrees. Internal gears do not

cause direction reversal.

Gear Design

Gear designs vary depending on the requirements for rotation speed, degree of

gear reduction and torque loading. Transmissions commonly use spur gears, while

hypoid gear designs are usually employed as the main gearing in differentials.

Common gear types include:

Spur

Spur (straight cut) gears are widely used in parallel shaft applications, such

as transmissions, due to their low cost and high efficiency. The design allows

for the entire gear tooth to make contact with the tooth face at the same

instant. As a result, this type of gearing tends to be subjected to high shock

loading and uneven motion. Design limitations include excessive noise and a

significant amount of backlash during high-speed operation.

Helical

Helical gears differ from spur gears in that their teeth are not parallel to

the shaft axis; they are cut in a helix or angle around the gear axis. During

rotation, parts of several teeth may be in mesh at the same time, which reduces

some of the loading characteristics of the standard spur gear. However, this

style of gearing can produce thrust forces parallel to the axis of the gear

shaft. To minimize the effects, two helical gears with teeth opposite each

other are utilized, which helps to cancel the thrust out during operation.

Double Helical (Herringbone)

Double helical gears, or herringbone gears, overcome the problem of

axial thrust presented by "single" helical gears, by having two sets

of teeth that are set in a V shape. A double helical gear can be thought of as

two mirrored helical gears joined together. This arrangement cancels out the

net axial thrust, since each half of the gear thrusts in the opposite

direction. However, double helical gears are more difficult to manufacture due

to their more complicated shape. Herringbone gears are capable of transmitting

large amounts of horsepower and are frequently used in power transmission

systems.

Bevel

Bevel gears (straight and spiral cut) transmit motion between shafts that are

at an angle to each other. Primarily found in various types of industrial

equipment as well as some automotive applications (differentials), they offer

efficient operation and are easy to manufacture. As with spur gears, they are

limited due to their noisy operation at high speeds, and are not the top choice

where load carrying capacity is a requirement. Bevel gears with equal numbers

of teeth and shaft axes at 90 degrees are called miter gears.

Hypoid

Hypoid gear sets are a form of bevel gears, but offer improved efficiency and

higher ratios over traditional straight bevel gears. Commonly found in axle

differentials, hypoid gears are used to transmit power from the driveline to

the axle shafts.

Worm

Worm gear sets employ a specially-machined “worm” that conforms to the arc of

the driven gear. This type of design increases torque throughput, improves

accuracy and extends operating life. Primarily used to transmit power through

non-intersecting shafts, this style of gear is frequently found in gear

reduction boxes as they offer quiet operation and high ratios (as high as

100:1). Downfalls with this type of gear set are its efficiency, high price per

HP and low ratios (5:1 minimum).

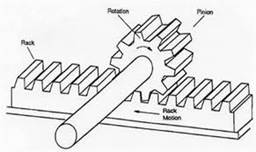

Rack and pinion

A

rack and pinion is a type of linear actuator that comprises a pair of gears

which convert rotational motion into linear motion. A rack is a

toothed bar or rod that can be thought of as a sector gear with an infinitely

large radius of curvature. Torque can be converted to linear force by meshing a

rack with a pinion: the pinion turns; the rack moves in a straight line. Such a

mechanism is used in automobiles to convert the rotation of the steering wheel

into the left-to-right motion of the tie rod(s).

Planetary

Planetary gear sets, such as those found in automatic transmissions, provide

the different gear ratios needed to propel a vehicle in the desired direction

at the correct speed. Gear teeth remain in constant mesh, which allows for gear

changes to be made without engaging or disengaging the gears, as is required in

a manual transmission. Instead, clutches and bands are used to either hold or

release different members of the gear set to get the proper direction of

rotation and/or gear ratio.

|

|

|

|

Rack and Pinion |

Planetary Gear |

Shifting of gears

In

some machines (e.g., automobiles) it is necessary to alter the gear ratio to

suit the task, a process known as gear shifting or changing gear. There are

several ways of shifting gears, for example:

- Manual transmission

- Automatic transmission

- Derailleur gears which are actually sprockets in combination with a roller chain

- Hub gears (also called epicyclic gearing or sun-and-planet gears)

There are several outcomes of gear shifting in motor vehicles. In the case of vehicle noise emissions, there are higher sound levels emitted when the vehicle is engaged in lower gears. The design life of the lower ratio gears is shorter, so cheaper gears may be used (i.e. spur for 1st and reverse) which tends to generate more noise due to smaller overlap ratio and a lower mesh stiffness etc. than the helical gears used for the high ratios.