![]() Example:

Example:

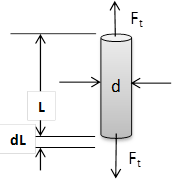

A tensile load of Ft = 24 kN is applied on a L = 160 mm

cylindrical rod made of steel EN8,and has a diameter d=20 mm.

Taking a factor of safety SF = 6, Find if the tensile stress on the

rod exceeds the allowable stress or not.

Also, find the increase of rod length (dL) due the tensile load,

where the steel’s modulus of elasticity E = 190 GPa.

Find the optimum design for the rod. A) Material, B) Dimensions.

Given:

Given:

Ft = 24000 N

d = 20 mm

FS = 6

E = 190 GPa

Req.:

- If σt < σall or σt > σall

- dL

Solution:

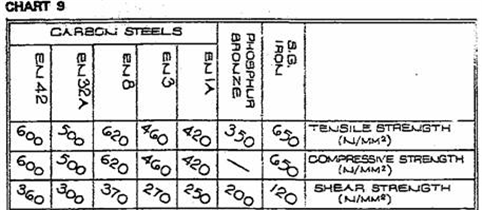

From Chart 9

σu = 620 MPa

σall = σu / SF = 620/6 = 103.33 MPa

σt =

F/A = F/(π/4

d2) = 24000/(π/4 202)

= 24000/314.16 =76.39 MPa

σt < σall (OK) OK

![]() E = σt

/ε = σt /(dL/L)

E = σt

/ε = σt /(dL/L)

dL/L = σt / E = 76.39/190000 = 4.02 x10-4

dL = 4.02 x10-4 L = 4.02 x10-4 x 160 = 0.064 mm dL = 0.064 mm

A) Choose another material, d = 20 mm:

σall = σt = 76.39 MPa

σu = σall x SF = 76.39 x 6 = 458.34 MPa

From Chart 9 we choose steel EN3 (σu = 460) EN3

B) Change rod dimensions, (EN8):

σt = σall = 103.33 MPa

σt = Ft /A

A = Ft / σt = 24000/103.33 = 232.27 mm2

π/4 d2 = 232.27 mm2

d = SQRT(4 x 232.27 / π ) = SQRT(295.73) = 17.2 mm d = 17.2 mm