Helical (Coil) Springs

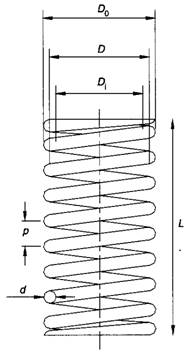

The figure shows a helical coil spring with ends adapted to support a compressive load. The notation applied are:

|

P = axial load, N D = mean diameter of coil, mm = (Do + Di) / 2 d = diameter of wire, mm = (Do – Di) / 2 p = pitch of coils, mm δ = deflection of spring, mm n = number of active coils C = spring index = D/d = (Do-d)/d = (4 : 12); less than 4; it is difficult to manufacture, more than 12; it is likely to buckle. G = torsional modulus of elasticity, N/mm2 τs = shearing stress, N/mm2 |

|

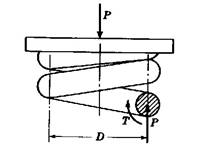

Stresses on coil spring (t):

The coil spring wire is subjected to the following stresses:

a- Torsional stress due to the load P

b- Direct shear stress due to load P

c- Torsional stress due to wire curvature

Torsional stress due to load P:

![]()

In order to include the effects of both direct shear and wire curvature, a stress factor (Kw) had been determined by the use of approximate analytical methods developed by A. M. Wahl:

![]()

which may be used in the above equation to determine the maximum shearing stress in the wire as follows:

![]()

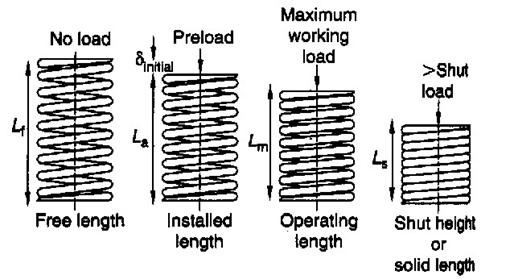

Various lengths associated with a spring:

Lf = Free length

La = Installed length

Lm = Operating length

Ls = Shut height or Solid length

· Compression springs in which the free length is more than four times the mean diameter of the coils may fail by sidewise buckling.

Spring deflection (d):

![]()

Spring rate (stiffness) (k):

![]()

Spring ends conditions:

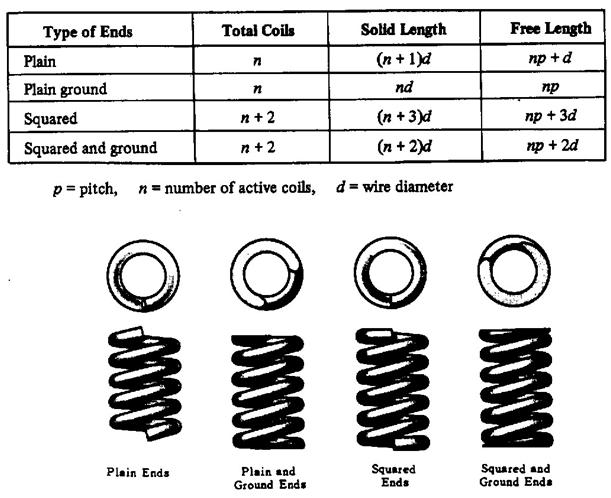

Helical springs ends may be either plain, plain ground, squared, or squared and ground as shown in the figure below. This results in a decrease of the number of active coils and affects the free length and solid length of the spring as shown below.

p=(D/3 : D/4), n= ( 3: 15)

Finding spring stress and deflection:

a- Using the above equations of tmax , and d.

b- Using the nomogram

c- Using the Excel program given

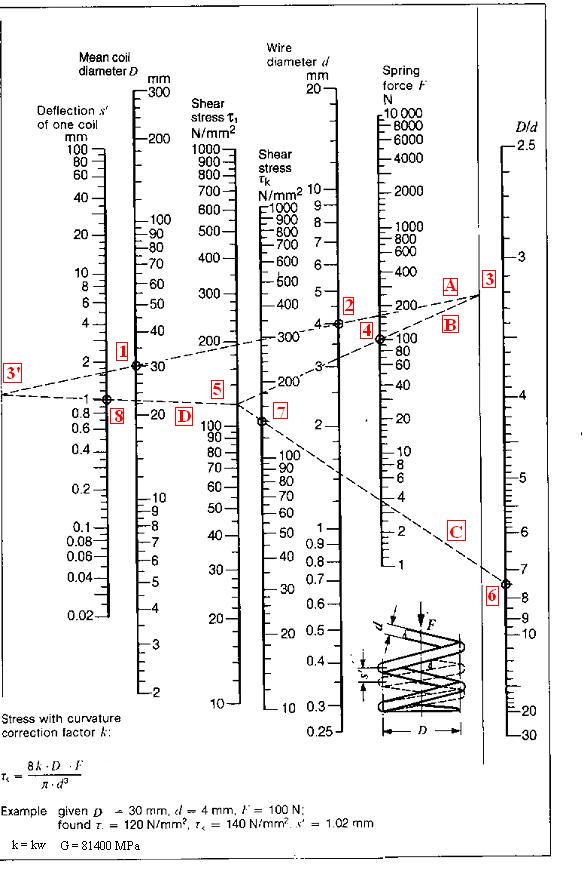

Explanation of the nomogram:

The nomogram applies to cylindrical helical extension and compression springs made of round steel wire (shear modulus G=81,400 N/mm2). In the case of materials with a different shear modulus G’ spring deflection must be multiplied by G/G’.

The nomogram indicates the deflection s’ of one coil. Total deflection s (d) is obtained by multiplying (s’) by the number of active coils n:

s (d) = n . s’.

Example:

Find the stress and the deflection of a spring with the following dimensions:

D = 30 mm

d = 4 mm

F = P = 100 N

Solution steps:

1- enter the value of D (point 1), and d (point 2) into the nomogram

2- connect point 1, 2 with the line A and extend the line to points 3 and 3’ on either end.

3- enter the value of F (point 4) into the nomogram

4- connect point 3 to the value of the force F (point 4) with line B, extend the line B to point (5)

5- calculate the value of C and enter its value into the nomogram (point 6)

6- connect point 6 and 5 by line C to obtain point (7)

7- connect point 5 to point 3’ to obtain point (8)

Solution:

- point 5 represents the value of tt (MPa)

- point 7 represents the value of tmax (MPa)

- point 8 represents the value of d’ = d/n (mm)

- enter the values of d, D, P, n, G.

The program will give you the values of C, Kw, tt (Tau”) , tmax (Tau), d/n (Delta”), d (Delta), and K