K.M. Mourad, T.A. Nosseir

Automotive Department,

Faculty of Engineering,

Ain Shams University Abbasia,

Cairo, Egypt. (kmourad@netscape.net)

|

A.A. Salem

The General Nile Direct

Transport Company,

Gisr El-Suez, Cairo, Egypt.

|

Abstract:

The success in the management of a

truck fleet depends upon many factors. An important one is how good the

preventive maintenance is executed. For that reason it should be a way or a

method which can be implemented to measure or to evaluate the execution of the

preventive maintenance. The objective of this work is to use the cost of repairs

of the fleet as a base to evaluate the efficiency of the execution of the

preventive maintenance, and to find a relationship between the level of executed

preventive maintenance and the cost of repairs. In this paper, a new parameter based on cost analysis

is introduced. This new parameter, namely the maintenance grade (MG) is used as

a measure or indicator of the preformed maintenance level in different working

places. A cost study employing the MG was carried out using real data obtained

from different branches of a goods transportation company. The fleet of the

chosen company is composed of trucks of different makes and having different

operating lives. The relationship between the MG for the fleet of tucks and the

costs of the truck's maintenance and repairs was studied. Results obtained

provide insight into the execution level of preventive maintenance and its

relationship to repairs cost.

1. Introduction

Running a

big fleet of trucks efficiently, as in the case of goods transportation

companies, depends in the first place on the level of executed maintenance (EM)

applied to the trucks. The executed maintenance can be divided into two main

types. The first type is known as the scheduled maintenance and referred to as

preventive maintenance (PM), where

the second type is referred to as repairs. The preventive maintenance (PM) is a

group of different preventive activities that are performed at predetermined

intervals, based on either time, distance traveled, engine working hours, or

quantity of fuel consumed. These intervals, of course, vary with the types and

makes of trucks and their operating conditions. Basically the truck manufacturer

recommends these intervals and the schedule which should be followed. This is

denoted as the planned preventive maintenance (PPM). Examples of the PPM

activities are oils change, oils topping, greasing, filters change, checking and

adjustment of different parts and systems of the trucks.

The other

type of maintenance (i.e. the repairs) can be divided into two kinds. The first

kind is the scheduled maintenance in which truck aggregates or some of their

parts are to be replaced. Examples of such repair activities are servicing of

truck systems (braking, cooling, steering,....etc.), and the overhauling of

truck main components (engine, gearbox,....etc.). The second kind of repairs is

the unscheduled maintenance due to components failure or road accidents.

Examples of such repair activities are body, aggregates and chassis heavy

repairs.

The negligence in performing the preventive maintenance, either in its execution

efficiency or its execution rate, will lead to an increase in the repairs

activities, especially unscheduled maintenance which results from breakdowns of

truck components. The unscheduled maintenance is considered the most costly and

should be minimized, as it will never be eliminated.

The objective of this investigation is to obtain the relationship between the

level of the executed preventive maintenance (EPM) for trucks and their cost of

repairs. From this relation the efficiency of the executed preventive

maintenance can be judged. In carrying this investigation a variety of trucks of

different makes and different operating lives are considered.

2. Infield Data

A goods

transportation company had been selected to be the source of data for this

study. The chosen company had to fulfill the following requirements:

- It has a big fleet composed of different truck makes

having different operating lives.

- The fleet is distributed over several company

branches (different working places).

- The company suffered no shortage in spare parts

or labor force during the period of the study.

- The company has good and reliable records and

documentation system.

3. Approach

In order to

judge the efficiency of the executed preventive maintenance in general, there

are different parameters that could be employed. These parameters are:

- Rate of

trucks brake downs.

- Cost of

repairs.

- Rate of

working mileage.

- The

financial return from running the trucks.

All the

above parameters depend to some extent on the working conditions and the

transportation company management policy. Therefor the above parameters can not

be used accurately to compare two different working places. Hence, a new

parameter has been proposed in this study as a quantitative measuring scale,

which is to be used as a measure or an indicator for the level of performing the

executed preventive maintenance. This new parameter which is referred to as the

maintenance grade (MG) is basically based on the cost analysis and is used

throughout the study as comparative means for judging the level of EPM. The MG

is intended to be used as a measure to compare the efficiency of performing the

maintenance work in different working places; considering that the level of

labor skills and the operation conditions are the same in each working places.

The MG is

defined as the ratio of the cost of EPM to the cost of PPM. Thus it can be put

in the form:

Cost of EPM

MG = ------------------,

(1)

Cost of PPM

where the

costs of both the EPM and PPM are calculated for the same distanced covered by

the truck. The planned preventive maintenance is the maintenance schedule

recommended by the truck manufacturer. In this study both costs do not include

labor or overhead costs as well as the loss due to truck breakdown time.

4. Data Collection and Processing

To reach the

objective of this study, which is mainly to obtain the relationship between the

level of performing EPM and the cost of the spare parts used in repairs, the

infield information is essential. The type of information or data needed from

the selected transportation company is the cost of EPM, the cost of PPM and the

cost of repairs for the fleet of trucks at each company branch. The data was

collected from the documentation of the company and tabulated in specially

designed data sheets. The data sheets were designed to contain the information

of each "sample group" in each branch. The sample group is defined here as the

group of trucks, which has the same make and has the same operating life and

located in one branch. The data was collected for a "sample period"

corresponding to the fiscal year (June 1990 to May 1991). The following

information was collected in these data sheets (for each sample group in the

sample period):

- Operation

data: (the distance covered by the trucks and

their financial return).

-Preventive maintenance data: (amount of oil and grease

consumed, in addition to the kind and number of oil, fuel, and air filters).

- Repairs data: (spare parts used for maintaining the

trucks, also the spare parts used in overhauling trucks’ aggregates and in

repairing the truck road accidents, in

addition to the number of tires and batteries used.

- Unit price data: (the price of each replaced unit and

the price of the used quantity of fluids).

The repair

cost is calculated by multiplying the number of spare parts used in repairs by

the price of each part. The price of spare parts is taken from the price list at

the time of the sample period. In this study only the repairs connected to the

maintenance activities is considered. Thus, the following repair costs were

excluded from the value of repair cost:

- repair

cost due to road accidents,

- replacement of tires and batteries, also, the cost of

engines and gear boxes overhauls, since their operating lives exceed the sample

period.

The EPM cost

for each sample group in the sample period is collected from the documentation

of the company. The EPM cost is calculated by multiplying the quantities of

material and spare parts used by their prices. At the same time the costs of PPM

are calculated as shown in Appendix (A). From the resulting information of the

EPM and PPM costs, the maintenance grade MG for each sample group is calculated.

In order to make the comparison between different sample groups more obvious;

the cost rate is employed in drawing all figures. The cost rate is defined as

the cost of maintenance or repairs in the sample period divided by the total

distance traveled by the trucks of the sample group in the sample period

(L.E./1000 km). The repairs cost rate (RCR), the executed preventive maintenance

cost rate (EPMCR) as well as the total cost rate (TCR) are drawn in one chart,

named the (MG-maintenance cost rate chart). Each point in the chart represents

the cost rate of a sample group. This set of curves in the cost rate chart is

expected to be similar to the well known chart of maintenance and repairs costs

shown in Figure 1.

5. Results

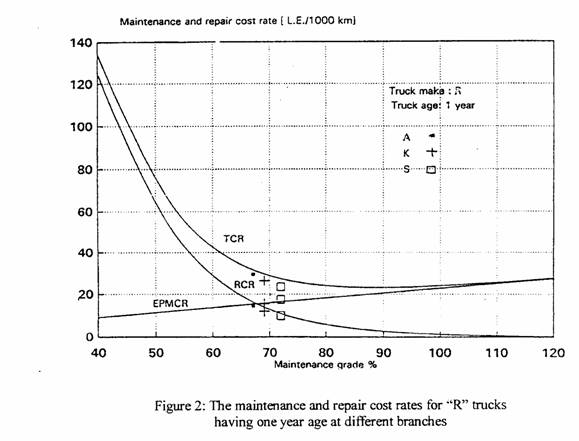

Knowing the

trend shape of the cost rate curves and using a suitable curve fitting computer

program; the curve connecting the points in the chart is drown. From Figure 2,

which represents the MG-maintenance cost rate chart, the following could be

drawn:

1-The executed preventive maintenance cost rate (EPMCR)

can be represented by a straight line in the form:

y1

= a x,

(2)

where: y1

is the cost rate of EPM (L.E./1000 km traveled), x is the MG (%), a is a

constant, representing a slope which depends on the truck make.

2-The repairs cost rate (RCR) can be represented by an

exponential curve with negative power plus a constant

in the form:

y2 = c e-b x + d,

(3)

where: y2

is the rate of RC (L.E./1000 km traveled), x is the MG (%), c, b, d are positive

real constants depending on the truck make and its operating life.

3-The total cost rate (TCR) is the summation of the

above two cost rates and its curve can be represented in the form:

y = y1 + y2,

(4)

y = ax + ce-bx + d.

(5)

4-The curve of the total cost rate has a minimum value

that can be obtained by differentiation of equation (5) and equating the result

to zero. The optimum value of MG will be equal to:

x = (1/b) ln (bc/a).

(6)

6. Discussion

As mentioned before the repairs cost due to road accidents and the cost of

overhauling of main truck components as well as the cost of the replacement of

tires and batteries have been excluded from the cost of repair. Also, the cost

of labor, tool and equipment depreciation or capital cost will not be included

in this study as they are outside the scope of the present work.

The data was

collected for different sample groups. The MG values were calculated alongside

the maintenance and repairs rates. The MG-maintenance cost rate charts are then

plotted for different sample groups. In the figures presented here each point in

the curve represents a sample group, this sample group was referred to by a

different letter and number (R6, KW10,.... etc.). Each letter represents a truck

make, while the number denotes its operating life (age). From the figures it can

be seen that increasing the MG value, which in turn means increasing the rate of

EPM cost, will lead to a decrease in the rate of repairs cost. From the figures

the repairs cost rate is different for trucks having the same make but having

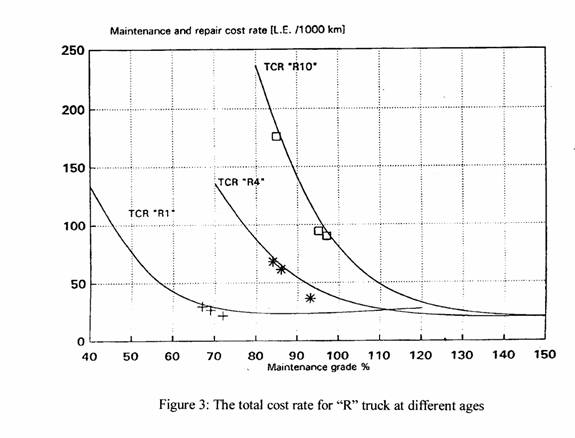

different operating lives. Figure 3 shows the MG-maintenance cost rate chart for

different truck ages. From this figure it can be seen that as the truck age

increases the corresponding slope (MG) increases. From these slopes one can

conclude that, the greater the operating life of the truck the more sensitive

the truck is to the change in MG value. The increase in the repair cost rate for

old trucks can be seen clearly. The old truck curve is shifted upwards and to

the right. The shift to the right can be due to the EPM operation not being

carried out as scheduled for new trucks, but is carried out most of the time

when the truck is stopped for the repairs (unscheduled maintenance). The other

reason for the increase in the EPM cost for old trucks is also due to the cost

of oil topping up the engines and gearboxes (bad gaskets and oil seals). The

small values of MG for new trucks are contributed to the poor maintenance

operation (long time intervals between executing the PM).

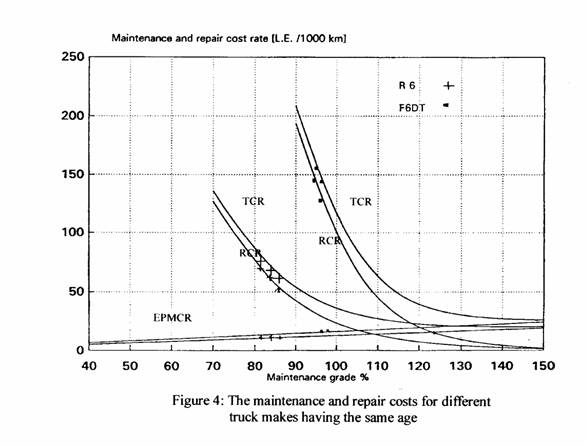

To find out

the effect of truck makes on the repair cost, two sets of data were used to draw

Figures 4. Presented in Figure 4 is the MG-maintenance cost rate for two truck

groups having the same operating life. From these curves one can see that in

general, increasing the maintenance level decreases the repairs cost. The slopes

of the maintenance curves are a little different due to the difference in the

volume of oil used and the number and cost of filters involved in the

maintenance operation. Though the maintenance cost rate is nearly the same for

the two makes, there is a big difference in the repair cost rate. This

difference is mainly due to the difference in the price of the spare parts.

When the

MG-maintenance cost rate charts were examined thoroughly two cases were observed

in some of the sample group data, which are considered here as abnormal ones and

deserved close study. In the first case although the EPM cost is greater than

the PPM cost, which lead to an increase in the MG value, no decrease is observed

in the repair cost. This indicates that there was overdoing of the maintenance

operation, yet it had little or no effect on maintaining the trucks. After

infield investigation it was found that, the obvious reason was due to abnormal

increase in the cost of the oil used. The increase in oil consumption is

attributed to the following causes:

-the change of engine oil does not follow the

manufacturer recommendation but takes place at shorter intervals,

- a great amount of oil is used during the period of

running-in the engines and gearboxes after conducting the overhauling,

- bad

gaskets and oil seals lead to repeatedly topping-up

of the engine oil in the period between two

successive engine oil changes,

- the bad habit of the garage technicians of topping up

the engine oil over the level indicated by the engine dip stick.

In the

second case, the EPM cost is found to be much less than the PPM cost (unusual

low value of MG) and is accompanied by high repair cost. That is thought to be

due to abnormal circumstances in maintenance operations practice. This case is

investigated closely and the results can be summarized as follows:

- shortage occurred in some of the high priced filters,

due to bad company administration policy.

- the maintenance operation is not performed correctly

(as in the case of greasing which lead to abnormal replacement of universal

joints and intermediate supports of the propeller shafts).

7. Conclusions

Several results from the analysis of the data were obtained. Several conclusions

can be drawn based upon these results. The main conclusions that were drawn from

the obtained results are as follows:

1- Evaluation of different truck makes and the level of

performing their preventive maintenance can be done based on the cost-analysis.

2- The defined parameter, MG, can be used successfully as a

measure of the level of maintenance executed in the different working places.

3- The MG-maintenance cost rate chart could be used to

evaluate the effectiveness of executing the PPM operations in the

different branches of the transportation companies.

At the same time, it could be used to show the effect of the operating life of

each truck make on the total cost rate at a later stage, when making the

decision of buying new trucks.

4- Increasing the maintenance level MG leads to a decrease in

the repair cost rate. There is an optimum

MG value which corresponds to the

minimum total cost rate. These optimum values depend on truck make and age and

also depend on maintenance and working conditions.

5- The old trucks (with higher operating lives) are very

sensitive to negligence of performing the preventive maintenance than the new

ones.

6- The MG-maintenance cost rate can be used to reschedule and

modify the PPM with respect to:

-the truck operational life; so the executive interval of

PPM should be shortened as the truck operational life increases.

-the truck make; taking into consideration the working and execution maintenance

conditions.

8. References

1-Salem, A., Feasibility Study of Preventive

Maintenance Implementation",

M.Sc. Thesis, Ain Shams University, Cairo, Egypt, 1992.

9. Acknowledgment

The authors

of this paper wish to express their gratitude to the personnel of the General

Nile Direct Transport Company for helping in providing the necessary data and

documentation.

APPENDIX (A)

Calculation of the PPM Cost

The PPM is scheduled according

to the manufacturer’s recommendation, to be carried out every certain distance

traveled by the truck. The PPM consists of three main types of maintenance,

namely maintenance A, B and C, which are carried out every 5,000, 10,000 and

40,000 km respectively. For each type of maintenance, A, B, and C there are

several different operations which are to be carried out.

To calculate the cost of the PPM for each sample group in the sample period,

some steps were followed. First, the total distance traveled (TDT) by the trucks

in each sample group were collected from the company documentation. Second, the

number of each type of scheduled maintenance were calculated according to the

following:

Number of

maintenance C (NC)

TDT

NC = ---------,

(7)

40,000

Number of

maintenance B (NB)

TDT

NB = -------- - NC,

(8)

10,000

Number of

maintenance A (NA)

TDT

NA = --------- -

(NC + NE). (9)

5,000

The cost of

each operation executed in each maintenance type was obtained from the price

list during the sample period. The cost of all operations in each type of

maintenance was summed up for each sample group. Finally, the total PPM cost was

obtained by multiplying the cost of each maintenance type by its number, then

added them together.

APPENDIX (B)

List of Symbols

EM acronym

for executed maintenance.

EPM acronym for executed preventive maintenance.

EPMCR acronym for executed preventive maintenance

cost rate

MG acronym for maintenance grade.

NA acronym for number of maintenance

type A.

NC

acronym for number of maintenance type C.

NE acronym for number of maintenance

type B.

PM acronym for preventive maintenance.

PPM acronym for planned preventive maintenance.

RC acronym for repair cost.

RCR acronym for repairs cost rate

TCR acronym for total cost rate (RCR+EPMR)

TDT acronym for total distance traveled

by the trucks

in the sample group during the sample period.