Basics

The thing that allowed the 1951 Chrysler HEMI to

produce so much more power than other engines of the day was the efficiency of

the combustion chamber

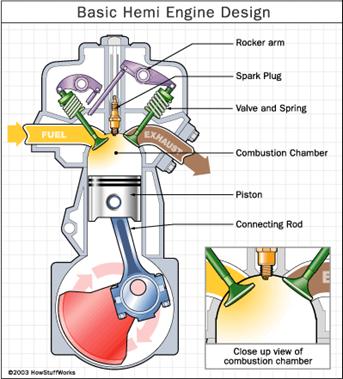

In a HEMI engine, the top of the combustion chamber is hemispherical, as

seen in the image above. The combustion area in the head is shaped like half of

a sphere. An engine like this is said to have "hemispherical heads." In a HEMI

head, the spark plug is normally located at the top of the combustion chamber,

and the valves open on opposite sides of the combustion chamber.

Most cars prior to the 1950s used what was known

as a flat head, and many lawn mower engines still use the flathead design

today because it is less expensive to manufacture. In a flathead engine, the

valves are in the block, rather than in the head, and they open in a chamber

beside the piston.

Advantages

There are many different parts of an engine's design

that control the amount of power you can extract from each combustion stroke.

For example:

- You want to burn all of the gas in the cylinder. If the design

leaves any of the gas unburned, that is untapped energy.

- You want the maximum cylinder pressure to occur when the

crankshaft is at the right angle, so that you extract all of the energy from

the pressure.

- You want to waste as little of the engine's energy as

possible sucking air and fuel into the combustion chamber and pushing

exhaust out.

- You want to lose as little heat as possible to the heads

and the cylinder walls. Heat is one of the things creating pressure in the

cylinder, so lost heat means lower peak pressures.

The last item in the list is one of the key advantages of the HEMI

head versus the flathead engine. Surface area causes heat loss. Fuel that

is near the head walls may be so cool that it does not burn efficiently. With a

flat head, the amount of surface area relative to volume of the combustion

chamber is large. In a HEMI engine, the surface area is much smaller than in a

flat head, so less heat escapes and peak pressure can be higher.

Another factor with a HEMI head is the size of the valves. Since the

valves are on opposite sides of the head, there is more room for valves. The

engine design that preceded the HEMI was a wedge-shaped combustion chamber with

the valves in line with each other. The inline arrangement limited valve size.

In a HEMI engine, valves can be large so the airflow through the engine is

improved.

The HEMI Magnum engine has two valves per cylinder as well as two

spark plugs per cylinder. The two spark plugs help to solve the

emission problems that plagued Chrysler's earlier HEMI engines. The two

plugs initiate two flame fronts and guarantee complete combustion.

Disadvantages

If HEMI engines have all these advantages, why aren't

all engines using hemispherical heads? It's because there are even better

configurations available today.

One thing that a hemispherical head will never have is four valves per cylinder.

The valve angles would be so crazy that the head would be nearly impossible to

design. Having only two valves per cylinder is not an issue in drag racing or

NASCAR because racing engines are limited to two valves per cylinder in these

categories. But on the street, four slightly smaller valves let an engine breath

easier than two large valves. Modern engines use a pentroof design to

accommodate four valves.

Another reason most high-performance engines no longer use a HEMI design is the

desire to create a smaller combustion chamber. Small chambers further reduce the

heat lost during combustion, and also shorten the distance the flame front must

travel during combustion. The compact pentroof design is helpful here, as well.