Rear axle construction

In cases where

the rear suspension is non-independent, the type of axle used is either a dead

axle or a live axle. The former only has to support the weight of the vehicle,

where the latter has to fulfill this task and, in addition, contain a gear and

shaft mechanism to drive the road wheels.

Axle shafts:

The axle shaft

(half shaft) transmits the drive from the differential sun wheel to the rear

hub.

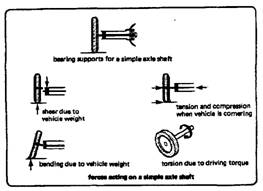

The various

types may be compared by considering the stresses the shaft has to resist. The

half shaft subjects to the following stresses:

|

1- Torsional

stress due to driving and braking torque.

2- Shear

stress due to the weight of the vehicle.

3- Bending

stress due to the vehicle.

4- Tensile and

compressive stress due to cornering forces.

|

|

The types of

axle shaft:

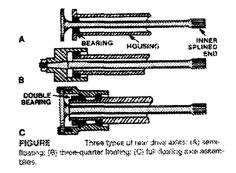

In addition to their other features of general construction, driving rear axles

are classified into three groups depending on the type of bearing mounting used

to support the hubs. The three arrangements classified as follows:

|

•

Semi-floating

•

Three-quarter floating

• Fully

floating

|

|

Semi-floating

rear hub:

A single bearing

at the hub end is fitted between the shaft and the casing, so the shaft will

have to resist all the stresses (shear, bending, torsional). In this

arrangement, if the axle shaft breaks, the driving wheel comes away from or out

of the axle housing.

Three-quarter-floating rear hub:

In

this construction the single bearing is located between the hub and the outside

of the axle casing. This relieves the shaft of shear load and bending loads due

to the vehicle’s weight, but it is still subject to bending loads due to

cornering side thrust, and torque. If the shaft fails, the wheel will still be

supported but side loads may cause it to rock on the bearing.

Fully

floating rear hub:

In this

construction the axle is supported by double taper-roller bearings on the

outside of the axle casing. In the frilly floating construction the axle shaft

transmits driving torque alone. The axle removal or failure does not affect the

road wheel, and the disabled vehicle can be towed to a service area to for

replacement of the axle shaft. This system is generally used with heavy

vehicles.

Special

transmission units:

a) Two speed axle;

this is a convenient method of providing a large number of gear ratios and

retaining a light gearbox. The torque applied to the final drive unit is also

moderate as the extra reduction and the increased torque are mad after the crown

wheel and pinion

Tw

(1st speed) = Te ig

ηt

i1, Tw

(2nd speed) = Te ig

ηt i2

where: i1,

i2

are the 1st and 2nd axle speeds respectively, and ηt

is the transmission efficiency.

b) Double reduction

axle; two reductions within the same unit

Tw

= Te ig

ηt

if = Te

ig

ηt

ia

ib

where: ia,

ib are the 1st and 2nd

reductions respectively.

c) Hub reduction;

a reduction made at the wheel hub reduces the stresses which would be applied to

the final drive unit having a large reduction ration. Fore example if a 2:1 hub

reduction is made this halves the torque to be transmitted to the axle shafts,

differential, crown wheel and pinion, propeller shaft and gearbox.

Tw = Te

ig ηt

if ih

where: if,

ih are the back axle

ratio and hub reduction respectively.