Universal Joints

A universal joint

is a mechanical connection between two shafts with interconnecting axes. It

provides positive drive whilst allowing angular movement of one or both shafts.

Hooke’s joint:

The Hooke’s type of joint or cross arrangement is

widely used, and consists of a four-legged spider or cross fitting into Y-shaped

yokes on each shaft, needle rollers normally being used to reduce friction.

Speed variation of

a Hooke-type coupling:

These joints do not

transmit the drive at uniform speed when deflected. During each revolution the

driven shat is subject to two accelerations and two decelerations whose values

depend upon the angle of deflection — usually limited to 20°.

When an intermediate

shaft, e.g. a propeller shaft, has Hook’s joints at each end, provided the yokes

and the angles of the deflection at each are equal, the cyclic variation of the

intermediate shaft will be cancelled out by the second joint. The speed

fluctuation of the intermediate shaft remains, and this has resulted in the

replacement of the Hook’s joints by constant-velocity joints in many

applications.

Double, back-to-bake, Hooke’s joints have been used as constant-velocity joints,

but are now replaced by more compact devices.

Constant-velocity joints:

One principle

for constant velocity (CV) depends upon the engagement between the two shafts

place in the plane bisecting the angle between them. In addition to providing

constant velocity these joints will operate at approximately twice the angle of

divergence (40-45°) of a Hooke’s joint, and are particularly used for the

outboard couplings on front-wheel drive.

The Propeller Shaft

The propeller

shaft connects the gearbox to a live rear axle or a sprung rear drive unit for

the front engine RWD vehicle. It revolves at engine speed in direct drive, and

accurate dynamic balance is essential to prevent vibration.

The critical

whirling speed where resonant vibration will occur is inversely proportional to

the square of the length. For example, if the maximum speed for a 1 m shaft is

5500 rev/mm, which for a 1.25 m shaft of the same type is only 3500 rev/mm.

In order to

obviate vibration and noise the shaft length may be reduced by a rearward

extension on the gearbox or a forward extension on the rear drive unit.

Alternatively a divided propeller shaft is often used. The propeller shaft is

normally tubular in section and is made in a one- or two-piece construction.

During manufacture, steel shafts are balanced and during this operation small

patches, are spot-welded on the ‘light parts’ of the tube to correct the

imbalance.

Some form of

‘sliding’ or ‘telescopic’ joint is required in the propeller shaft assembly, so

that it can accommodate itself to small variation in effective length of the

drive line.

Transmission

tunnel height:

|

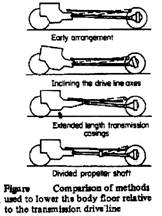

There are many

attempts to lower the car height, which in turn called for some lowering of

the body floor line. To provide the lowest possible transmission tunnel

height, thereby increasing rear seat foot room.

* The

propeller shaft either made of steel or composite material. The composite

propeller shaft has the advantage of less weight (50% reduction), high

internal shock absorption, and corrosion resistance.

|

|

Drive shafts

The drive shafts

connect to independently sprung front or rear road wheels. Being on the output

side of the final drive unit, they operate with that ratio of torque increase

and speed reduction compared with a propeller shaft.

In most cases

the shafts are of equal length and typically of 20-25 mm diameter nickel-

chromium steel. With a transversely mounted engine-transaxle unit,

unequal-length shafts may be required. The longer shaft can be partly of

larger-diameter tubular construction to equalize the torsional rigidity and

vibration characteristic with the shorter solid shaft.

The final drive and differential

The function

of final drive gears:

Final drive

gears are incorporated in vehicle driving axles for the following reasons:

·

To provide a

right-angle drive from either the propeller shaft, or the gearbox layshaft, to

the driven wheels.

• To permit an

additional and constant gear reduction in the transmission system. These

functions can be performed by bevel or worm gears.

The

final drive

The duty of the

final drive gears is to gear down the speed to suit the road wheels and redirect

the line of drive. A crown wheel and pinion bevel gear having a gear ratio of

about 4:1 is commonly used on cars but a lower ratio, e.g. 6:1 is necessary to

suit the large road wheels used on commercial vehicles;

v =

ωw

rw = [(2

π Ne/60) / (ig

if)] rw, TE

= Te

ηt

ig if / rw

Types of

bevel gear:

The hypoid gear

is in common use today

due mainly to the fact that the

offset pinion allows the propeller shaft to be set below, (for cars) or above,

(for commercial vehicles) the crown wheel centre. This gives either a reduction

in the/propeller shaft tunnel, which causes a bump in the vehicle floor, or in

the case of a commercial vehicle a reduction in the angle through which the

universal joint has to operate.

Worm and

wheel:

Today this

expensive form of drive is rarely used as a final drive on light vehicles, but

it is still used on heavy vehicles. Various arrangements, as shown in the figure

can be used to give a very quiet and long-lasting gear, but efficiency is not as

good as with the bevel (94 per cent against 98 per cent).

The back axle ratio

(final drive ratio) (if):

With the actual

gears he number of teeth on the crown wheel (the large cone) divided by the

number of teeth on the bevel pinion (the small cone) gives the ‘axle ratio’.

Also the gear ratio of a worm and wheel is given by dividing the number of teeth

on wheel by the number of starts on worm.

It should be

noted that a ‘high ratio’ axle refers in fact to one with a low numerical ratio.

For example, a final drive with an axle ratio of 4.10:1 is a ‘high ratio’ axle

as compared to one providing 4.56:1 ratio. In this connection, it will be

observed that the axle ration appears to be somewhat ‘fussy’ figure, such as

those just quoted. This is because the axle designer prefers to use an odd

number of teeth on the pinion so that each tooth on the crown wheel engages

every tooth on the pinion in regular succession.

Differentials

with a low (numerically high) gear ratio allow for fast acceleration and good

pulling power. Differential with high gear ratios allow the engine to run slower

at any given speed, resulting in better fuel conservation.

Special

transmission units:

a) Two speed axle;

this is a convenient method of providing a large number of gear ratios and

retaining a light gearbox. The torque applied to the final drive unit is also

moderate as the extra reduction and the increased torque are mad after the crown

wheel and pinion

Tw

(1st speed) = Te ig

ηt

i1, Tw

(2nd speed) = Te ig

ηt i2

where: i1,

i2

are the 1st and 2nd axle speeds respectively, and ηt

is the transmission efficiency.

b) Double reduction

axle; two reductions within the same unit

Tw

= Te ig

ηt

if = Te

ig

ηt

ia

ib

where: ia,

ib are the 1st and 2nd

reductions respectively.

c) Hub reduction;

a reduction made at the wheel hub reduces the stresses which would be applied to

the final drive unit having a large reduction ration. Fore example if a 2:1 hub

reduction is made this halves the torque to be transmitted to the axle shafts,

differential, crown wheel and pinion, propeller shaft and gearbox.

Tw = Te

ig ηt

if ih

where: if,

ih are the back axle

ratio and hub reduction respectively.

The differential

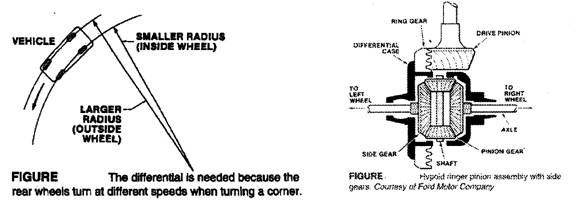

The differential

provides an equal torque to each half-shaft or drive shaft although they may be

rotating at different speeds. It therefore allows the outer road wheel to

revolve faster than the inner when cornering, whilst maintaining a positive

drive to both wheels.

Since no grater

torque can be transmitted to one road wheel than the other owing to the balance

action of the differential, if one road wheel is on a slippery surface where it

can revolve idly, no tractive force can be applied to the other wheel.

The limitation

of the differential -loss of drive if one wheel spines- can be eliminated by the

use of a differential lock, e.g. dog clutching one of the sun pinions to the

differential cage. Alternatively, a limited-slip differential (LSD) arrangement

with solid or viscous friction between the sun wheel and the differential cage

will apply some torque to the wheel having grip.

* The torque is

divided between the two wheels. The speed of inner and outer wheels can be

obtained from the following:

Let Nc

= rev/min of crown wheel or differential unit, Ni = rev/min of inner

wheel, and No = rev/min .of outer wheel. Then

Nc =

(Ni + No) /2

and

No

= (Nc x2) – Ni

or Ni = (Nc

x 2) - No

Rear axle construction

In cases where

the rear suspension is non-independent, the type of axle used is either a dead

axle or a live axle. The former only has to support the weight of the vehicle,

where the latter has to fulfill this task and, in addition, contain a gear and

shaft mechanism to drive the road wheels.

Axle shafts:

The axle shaft

(half shaft) transmits the drive from the differential sun wheel to the rear

hub.

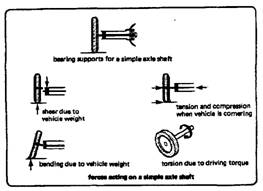

The various

types may be compared by considering the stresses the shaft has to resist. The

half shaft subjects to the following stresses:

|

1- Torsional

stress due to driving and braking torque.

2- Shear

stress due to the weight of the vehicle.

3- Bending

stress due to the vehicle.

4- Tensile and

compressive stress due to cornering forces.

|

|

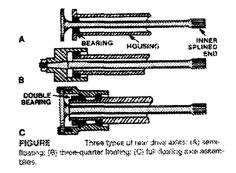

The types of

axle shaft:

In addition to their other features of general construction, driving rear axles

are classified into three groups depending on the type of bearing mounting used

to support the hubs. The three arrangements classified as follows:

|

•

Semi-floating

•

Three-quarter floating

• Fully

floating

|

|

Semi-floating

rear hub:

A single bearing

at the hub end is fitted between the shaft and the casing, so the shaft will

have to resist all the stresses (shear, bending, torsional). In this

arrangement, if the axle shaft breaks, the driving wheel comes away from or out

of the axle housing.

Three-quarter-floating rear hub:

In

this construction the single bearing is located between the hub and the outside

of the axle casing. This relieves the shaft of shear load and bending loads due

to the vehicle’s weight, but it is still subject to bending loads due to

cornering side thrust, and torque. If the shaft fails, the wheel will still be

supported but side loads may cause it to rock on the bearing.

Fully

floating rear hub:

In this

construction the axle is supported by double taper-roller bearings on the

outside of the axle casing. In the frilly floating construction the axle shaft

transmits driving torque alone. The axle removal or failure does not affect the

road wheel, and the disabled vehicle can be towed to a service area to for

replacement of the axle shaft. This system is generally used with heavy

vehicles.

Tires

Types of

tires:

The basic

variations in motor vehicle tire construction may be considered under the

following headings:

• Tube and

tubeless

A separate

rubber inner tube acting as a flexible bag to retain air introduced under

pressure early became an established feature of pneumatic tire Since mid

nineteen fifties it has become established practice for private cars, and to a

lesser extent for commercial vehicle, to dispense with the separate inner tube

in favor of an inherently air-tight or ‘tubeless tire’). The tubeless tire has

the following advantages: (increased safety, cooler running, and Improved

balance).

• Cross ply and

radial play

The radial ply

tire is relatively free from internal friction because of the non-criss-crossing

of its carcass plies. This in turn means cooler running and it permits reduced

inflation pressure for greater cushioning ability.

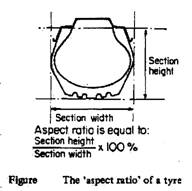

Tire aspect

ratio:

|

It is the

ratio of the tire inflated section height to section width for a specified

rim width. A modern radial ply tire with a ‘low’ aspect ratio is both wider

and shallower than an old fashioned cross ply tire with a ‘high’ aspect

ratio.

The ratio is

usually expressed as a percentage.

|

|