Leaf Springs and Torsion Bars

Leaf Springs

Acts as:

- an elastic element

- guide

- damper

+ they are easy to manufacturer and convincement

to repair

Disadvantage:

-

large

metal

content (energy stored in unit volume in spring or torsion bar is 4 times

more

than a leaf spring; that lead to increase metal content).

-

sufficient

unsprung mass

-

short

service

life.

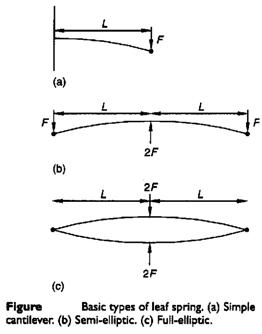

If it is desired to

maintain

uniform bending stresses over the length of the beam then the width of

the

cantilever needs to vary linearly with the location as illustrated in Figure

i,

(σb = M y/I = 12 F L y / b h3). The concept used

in

producing compact cantilever springs of uniform bending stress is to chop

the

triangular form illustrated in Figure i, into a number of strips and

recombine

them as illustrated in Figure ii. The multi-leaf spring shown and the

single

triangular section beam both have the same stress and

deflection

characteristics with the exceptions that the multi-leaf spring is subject

to

additional damping due to friction between the leaves and that the

multi-leaf

spring can carry a full load in only one direction due to the tendency for

the

leaves to separate. Leaf separation can be partially overcome by the

provision

of clips around the leaves.

The deflection of

a

triangular leaf spring is given by

Where

F is force (N)

L is the length (m)

E is the

Young’s

modulus (N/m2)

I is the

second

moment of area (m4)

For a

rectangular

cross-section,

Where b is width (m); and

h

is thickness (m).

The spring rate is given by

The corresponding

bending

stress (for cantilever, semi-elliptic and full-elliptic) is given by

For semi-elliptic beam

the

maximum deflection at the center is given by

For a full-elliptic beam

the

maximum deflection at the center is given by

* in the above equation

the

length b can be changed by (n b’) where n is the number of leafs

and

b’ is the width of single leaf. The leaf width b’

is

chosen from the available range of rolled products. It is desired that

the

following condition should hold

6 < b’/h

< 10

6 < n <

14

The spring length can

be

determined using the equations for spring stiffness and stress to obtain

Where

δ = is the

total deflection (δst + δd)

- Effect of adding an

extra

full length number of leaves (ne) to the graduate length number

of

leaves (ng):

That means the extra

leaves

will have more stress than graduate ones.

Torsion beam suspension (torsion bars)

Definition: A steel bar that is twisted to

support

the weight of the vehicle. Torsion bars are used in place of coil or

leaf

springs on some vehicles, and allow ride height to be adjusted to

compensate

for sage that occurs over time.

The bars are usually solid

of

circular cross section although hollow tubes and rectangular bars are used.

τall = 1000- 1050

MPa

The angle of twist and

stiffness

of a torsion bar are expressed as

The torsion-bar working length

L

(without spline ends) is determined by the θ equation. It is recommended

to choose the diameters and lengths of spline ends depending on the

torsion-bar

diameter

dsp =

(1.2

-1.3)d; and Lsp= (0.6-1.2)d

Suspension Formulae

Where b is the

width

of spring blade (m), L is the distance between the eyes of the

spring

when laden (m), t is the thickness of the blade (m), n is

the

number of blades, and E is the modulus of elasticity, which (modified

to

allow for internal friction) is 159 x 106 kN/m2.

For a torsion bar,

the

spring rate is given as the twisting moment per angular deflection. When

a

lever is added, this can be converted into a rate for the vertical

deflection

of the end of the lever.

Spring rate (torsion

bar,

for deflection at end of lever)

Where G is the

modulus

of rigidity, which is 78.5 x 106 kN/m2 in this case, d

is the diameter of the torsion bar (m), l is the effective length of

the

torsion bar (m), i.e. half the length of the bar for an anti-roll bar, and e

is the length of the lever (m).

Spring rate (coil spring)

Where G is the

modulus

of rigidity, which is 81.5 x 106 kN/m2 in this case, d

is the wire diameter (m), n is the number of free coils, and D

is

the mean coil diameter (m). To find the number of free coils it is necessary

to

subtract the number of dead coils form the total number of coils. The

dead

coils are those that provide the abutment and so cannot be deflected,

usually

1.5 to 2 coils.